Precison Machining Services

Get superior-quality precision CNC machining services for prototypes and production parts. Take advantage of advanced manufacturing solutions with competitive rates and short lead times.

- Instant CNC online quotes

- Free & Automatic DFM feedback

- Tolerances down to ±0.0004″ (0.01mm)

- Machined parts as fast as 1 day

Why Choose Our Precision Machining Service

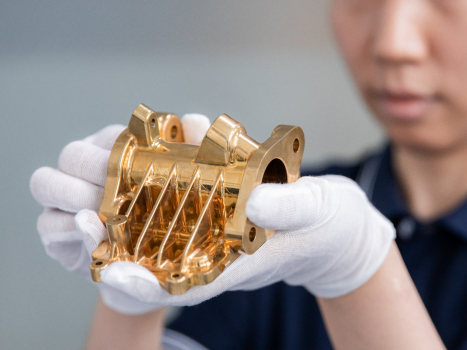

Bring your precision CNC machining parts to life through top-notch precision machining services. JTC CNC boasts cutting-edge manufacturing capabilities for high precision CNC machining. All prototypes and end-use parts meet strict quality standards and tolerance requirements.

High Precision and Tight Tolerances

Our CNC precision machining combines advanced technology with expert knowledge. As an ISO 2768 and ISO 9001:13485 certified company, we prioritize quality and ensure components meet specifications.

Rapid Prototyping and Production

We expedite your product development from prototyping to production. Our quick turnarounds turn designs into prototypes, enabling faster iterations and reduced time-to-market. Our CNC machining is scalable to any production volume.

Online Quoting and Ordering

JTC CNC online platform offers instant real-time pricing for parts with material and finish options. Order conveniently without waiting days for precision machining quotes!

DFM Analysis Support

Experience our platform's advanced machine-learning, pinpointing complex geometries for machining challenges. Receive a detailed DFM analysis for your CNC parts in minutes.

Advanced Manufacturing Facilities

At JTC CNC, our comprehensive equipment includes Precision CNC milling, turning, and EDM. From prototypes to mass production, we use top materials and technology. Our dedicated technicians work tirelessly for optimal product quality.

Dedicated Customer Support

JTC CNC boasts expert engineers ready to optimize your designs, cut costs, and enhance quality. Trust our team for exceptional advice and unmatched engineering support, ensuring top-tier project results.

Precision CNC Machining Capabilities

Effectively bring your products to market faster with a reliable CNC milling company. From rapid prototyping to custom production runs, take advantage of quality 3-axis, 4-axis, and full 5-axis CNC milling for highly accurate and quality CNC milling products. JTC CNC offers quality CNC milling services to help transform your designs into complex geometric shapes. Take control of your CNC milling projects by working with our in-house machining team and receive custom parts that meet your strict requirements.

JTC CNC wire EDM, part of our CNC services, efficiently crafts both simple and intricate shapes. Ideal for parts requiring high precision, this no-contact method produces minimal burrs and excels with metals like steel and titanium. Favored in aerospace, automotive, and electronics for their accuracy, we ensure tailored, precise solutions regardless of your needs.

tr>Cutting Speed Up to 300 mm2/min (specific to material and thickness)tr>Cutting Speed Up to 300 mm2/min (specific to material and thickness)

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (based on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Cutting Speed | Up to 300 mm2/min (specific to material and thickness) |

| Surface Finish | As fine as Ra 0.2 µm |

| Maximum Cutting Thickness | Up to 12 inches (300 mm) – varies based on material |

| Wire Diameter Range | 0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

Mirror EDM delivers mirror-reflective, high-precision parts. Capable of producing intricate shapes with tight tolerances, it excels on hard materials where conventional tools falter. Catering to industries from aerospace to electronics, our Mirror EDM ensures unparalleled precision, capturing intricate contours and complex geometries consistently.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Surface Finish | Achievable down to Ra 0.05 µm or better (based on material and process parameters) |

| Tolerance | ± 0.00005 inches (0.0013 mm) or better (depending on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm)

Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Maximum Cutting Thickness | Up to 10 inches (250 mm) – varies based on material |

RapidDirect’s advanced manufacturing facility features high-precision grinding machines, perfect for manufacturing metal parts with tight tolerances. Our versatile grinding excels from small parts to complex geometries. The precision wheels provide controlled material removal, ensuring polished finishes. This efficiency reduces costs, wear, and errors. Trust our expert team to guide you to the ideal grinding solution for your project.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Ceramics, Carbides |

| Grinding Methods | Surface Grinding, Cylindrical Grinding, Centerless Grinding, Internal Grinding |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (specific to material and grinding method) |

| Maximum Workpiece Size | Length: 24 inches (600 mm) Width: 10 inches (250 mm) Diameter: 8 inches (200 mm) for cylindrical grinding |

| Surface Finish | Achievable down to Ra 0.1 µm or better (based on material and grinding method) |

RapidDirect’s advanced CNC turning delivers unmatched accuracy and repeatability for machine parts and prototypes. Our diverse turning centers cater to varied applications, ensuring consistent precision across batches. With reduced errors, we offer quicker production without sacrificing quality. Rely on our technicians and top-grade CNC machines for exceptional component craftsmanship.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Turning Operations | External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Diameter | 20 inches (508 mm) or specific to machine capability |

| Maximum Workpiece Length | 60 inches (1524 mm) or specific to machine capability |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

RapidDirect’s multi-axis milling machines guarantee CNC parts with tight tolerances and precise dimensions. This technology delivers precision tailored to your needs, ideal for iterations and new products. Compatible with a broad material range, from metals to composites, our CNC milling boasts efficiency, having parts ready swiftly.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Milling Operations | Face Milling, Profile Milling, Pocket Milling, Complex Surface Milling, Drilling, Boring |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Size | X: 40 inches (1016 mm) Y: 20 inches (508 mm) Z: 25 inches (635 mm) or specific to machine capacity |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

Precision CNC Machining Capabilities

Effectively bring your products to market faster with a reliable CNC milling company. From rapid prototyping to custom production runs, take advantage of quality 3-axis, 4-axis, and full 5-axis CNC milling for highly accurate and quality CNC milling products. JTC CNC offers quality CNC milling services to help transform your designs into complex geometric shapes. Take control of your CNC milling projects by working with our in-house machining team and receive custom parts that meet your strict requirements.

Rapid Prototyping

Leverage our robust manufacturing capabilities for swift, high-quality prototype delivery. Using the latest technology, we ensure rapid, accurate production, expediting your path from testing to market.

Capability: 20-500

Lead Time: 10 business days

Low Volume Manufacturing

Our precision machining is suitable for low-volume production, offering fast delivery and unmatched accuracy. We ensure your projects meet high quality standards at reduced costs.

Capacity: 500-1000

Lead Time: 15 business days

High Volume Manufacturing

JTC CNC is equipped to handle large-scale production orders. This means that they can efficiently produce large quantities of precision machined parts without compromising on quality or precision.

Capacity: 1000+

Lead Time: 20 business days

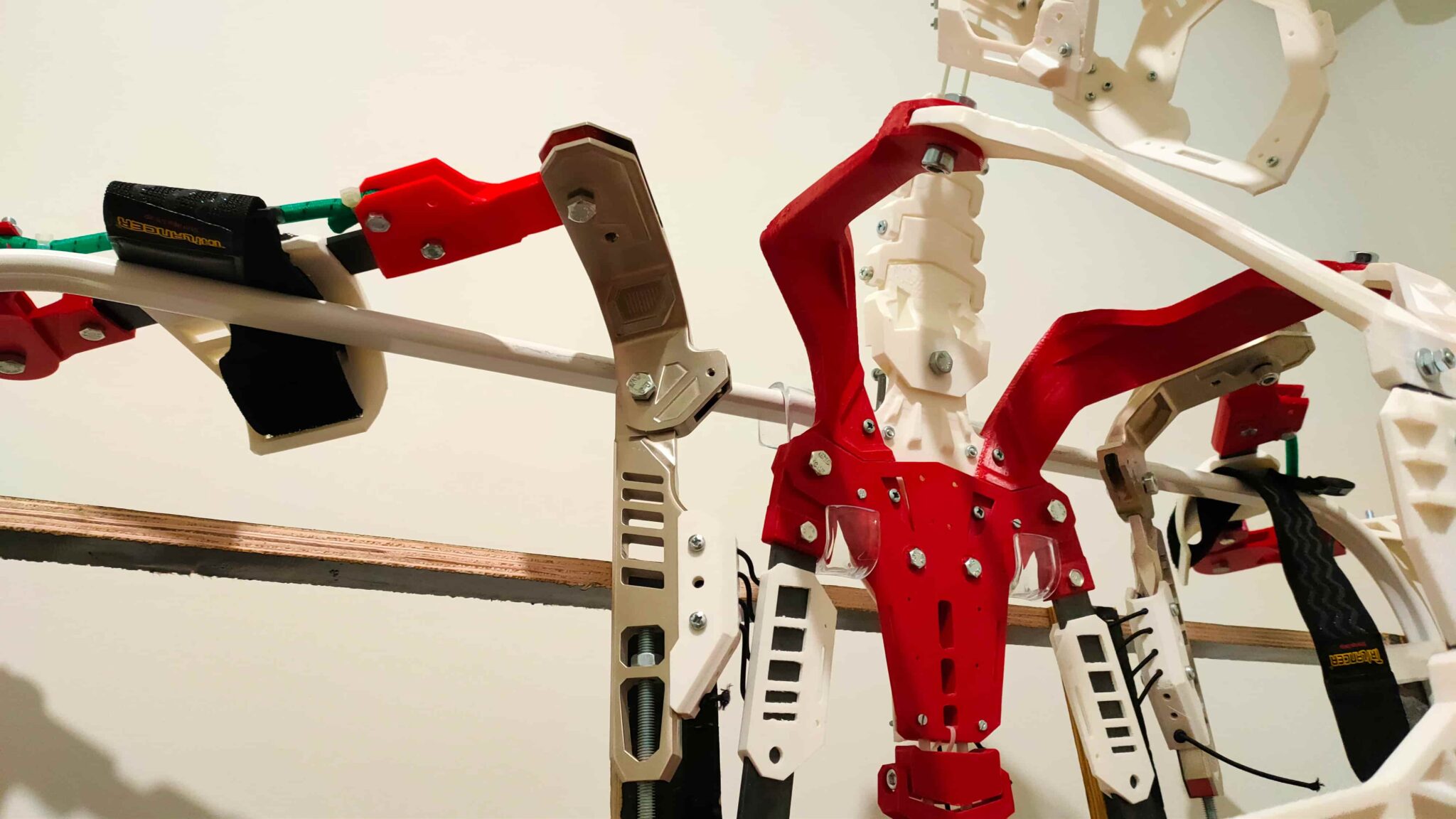

Precision Machined Ectoskeleton Parts

JTC CNC collaborated with Andrea Piccino to create premium exoskeleton components for the “Iron Man Suit.” Our advanced manufacturing capabilities was instrumental in fabricating the components with utmost precision. With cutting-edge 5-axis CNC machining, 45-degree angled machining, and electrical discharge machining, our experts were able to precisely create exoskeleton parts with multiple surfaces and intricate geometries.

Precision Machined Part Size Standards

| Classification | Minimum Size (mm) | Maximum Size (mm) | Common Applications |

| Ultra-Precision Components | 0.1 | 1 | Watch components, micro devices |

| Micro Machined Parts | 1.1 | 10 | Medical devices, small electronics |

| Small Machined Parts | 10.1 | 50 | Aerospace, automotive sensors |

| Medium Machined Parts | 50.1 | 200 | Automotive, defense, industrial tools |

| Large Machined Parts | 200.1 | 1000+ | Heavy machinery, construction |

Precision CNC Machining Tolerances

| Operation Type | Typical Tolerance (mm) | Best Possible Tolerance (mm) | Notes |

| EDM | ±0.015 | ±0.005 | Tolerance can be affected by electrode wear. |

| Grinding | ±0.005 | ±0.001 | Surface finish is typically smoother with grinding. |

| CNC Turning | ±0.025 | ±0.010 | Finish can impact tolerance. |

| CNC Milling | ±0.025 | ±0.005 | Precision can vary based on tool type and material. |

Materials for CNC Milling Parts

Depending on your applications, our CNC milling process is compatible with an extensive range of materials. We stock over 30 production-grade metal alloys for producing various CNC milled parts for different industries. In addition to metals, JTC CNC high-precision CNC milling service is also compatible with many plastic materials. Check out some of the widely used materials for CNC milling parts.

Materials for Custom CNC Machining Parts

At JTC CNC, we offer an extensive range of materials to meet the diverse needs of clients. Our commitment to excellence ensures that every custom CNC machining part we produce exhibits unmatched quality and precision. Whether you require metal components with exceptional strength or plastic parts with outstanding mechanical properties, our materials selection caters to various industries and applications.

Aluminum

Plastics

Aluminum

Metals

We offer an extensive selection of high-quality metal materials for different applications.

Plastics

Plastics

We also provide an impressive assortment of plastic materials designed to fulfill diverse manufacturing need.

Surface Finishes fo Pecision CNC Machining

At JTC CNC , we prioritize the aesthetics and functionality of your precision CNC parts. Our diverse surface finishes ensure custom-tailored precision. Trust in our commitment to enhance your projects with lasting excellence.

- As-machined finish

- Anodizing

- Bead blasting

- Powder coating

- Polishing

- Electroplating

- Passivation

- Brushed finish

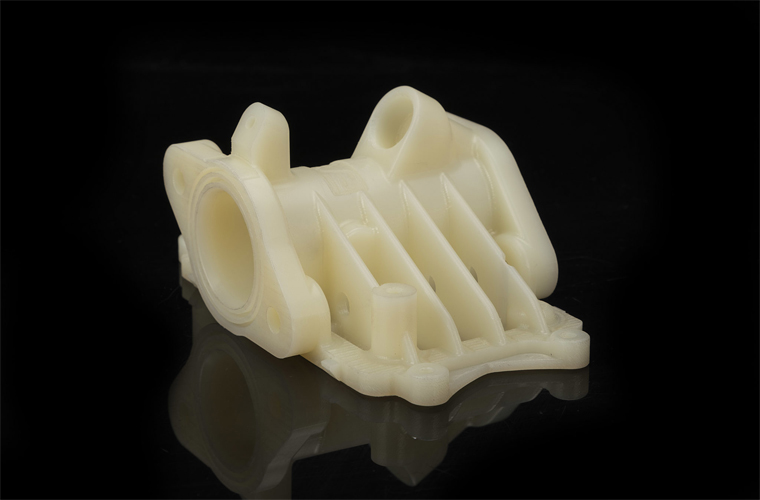

Gallery of CNC Milling Parts

Check out our extensive gallery that shows precision milled prototypes and parts from our valued customers.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Piscary Herskovic

Product Designer

Mark Alford

Chief Engineer

Luc Szorc

Mechanical Engineer

Kayne Espinosa

Project Manager

Hari Mackenzie

Engineer

Ultimate Guide to CNC Machining

Explore Related Resources

Multi-Axis Machining: 3-Axis vs 4-Axis vs 5-Axis CNC Machining

Selection of the right type of machine in multi-axis CNC machining is among the most crucial decisions. It determines the overall capabilities of the process, the designs that are possible, and the overall costs. 3-axis vs 4-axis vs 5-axis CNC machining is a popular debate and the right answer depends on the requirements of the project. This guide will…

CNC Machining Materials: Choosing the Right Materials for CNC Machining Project

CNC machining is inarguably the lifeblood of the manufacturing industry with applications such as aerospace, medical devices, and electronics. In recent years, there have been incredible advancements in the field of CNC machining materials. Their wide portfolio now offers great combinations of material properties, cost, and aesthetics. In this article, we will delve into the diverse world…

Plastic CNC Machining: Create Custom CNC Machined Parts with Accuracy

A common depiction of CNC machining, most times, involves working with a metallic workpiece. However, not only is CNC machining widely applicable to plastics, but plastic CNC machining is also one of the common machining processes in several industries. The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC…