Specifications

Pellentesque porta sed dolor id porta sed dolor id volutpat dolor nulla amet nulla volutpat dolor nulla - porta sed dolor id volutpat dolor nulla amet nulla. Vestibulum dolor condimentum pellentesque turpis, consectetur at mauris eget, condimentum pellentesque leo porta sed dolor id volutpat dolor nulla amet nulla lorem ipsum.

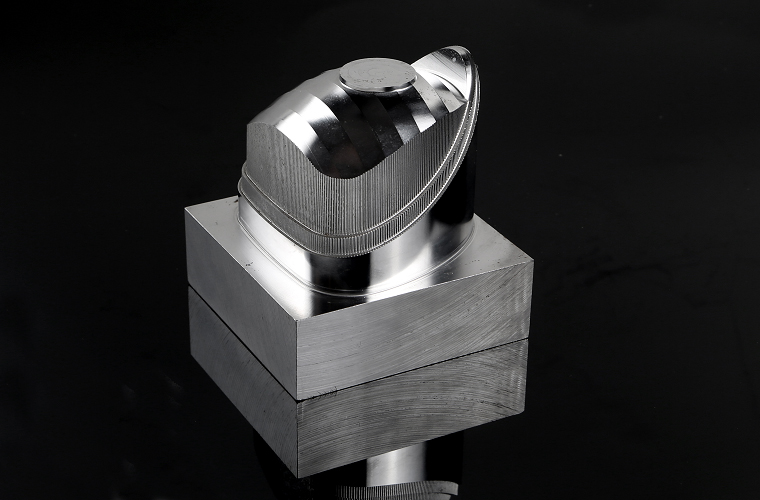

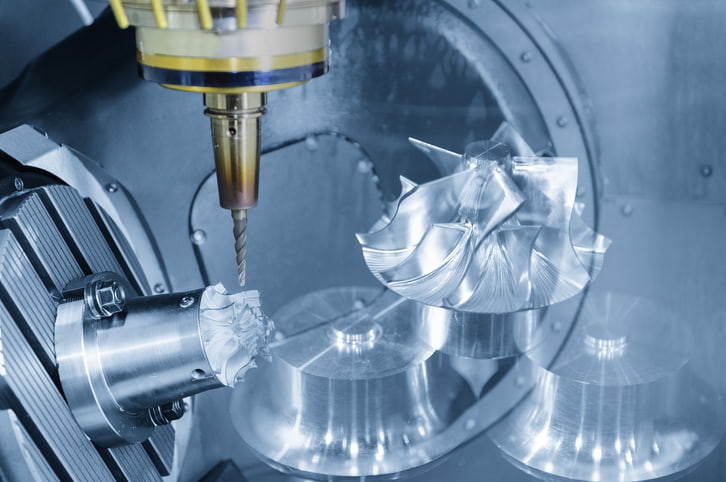

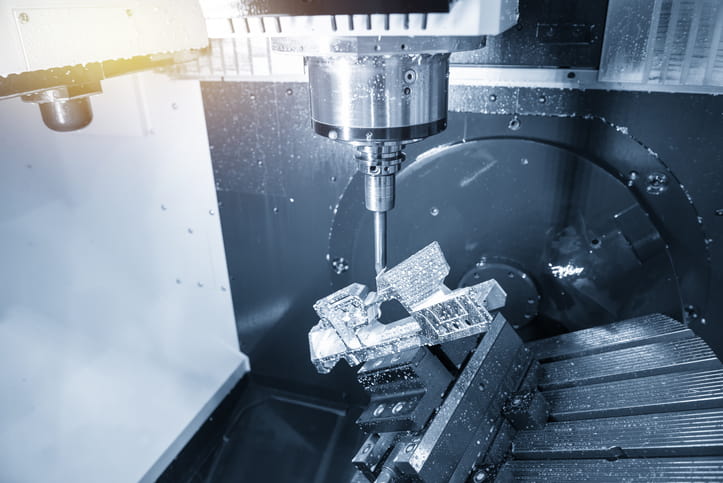

5 Axis CNC Machining Services

Get high-precision, accuracy, intricate machined parts with extremely complex geometries with our 5 axis CNC machining services. Competitive pricing and fast turnaround.

- Instant CNC online quotes

- Free & Automatic DFM feedback

- Tolerances down to ±0.0004″ (0.01mm)

- 24/7 engineering support

10S

Instant Quotes

1 day

Lead time

0 pc

MOQ

0.010 mm

Tolerances

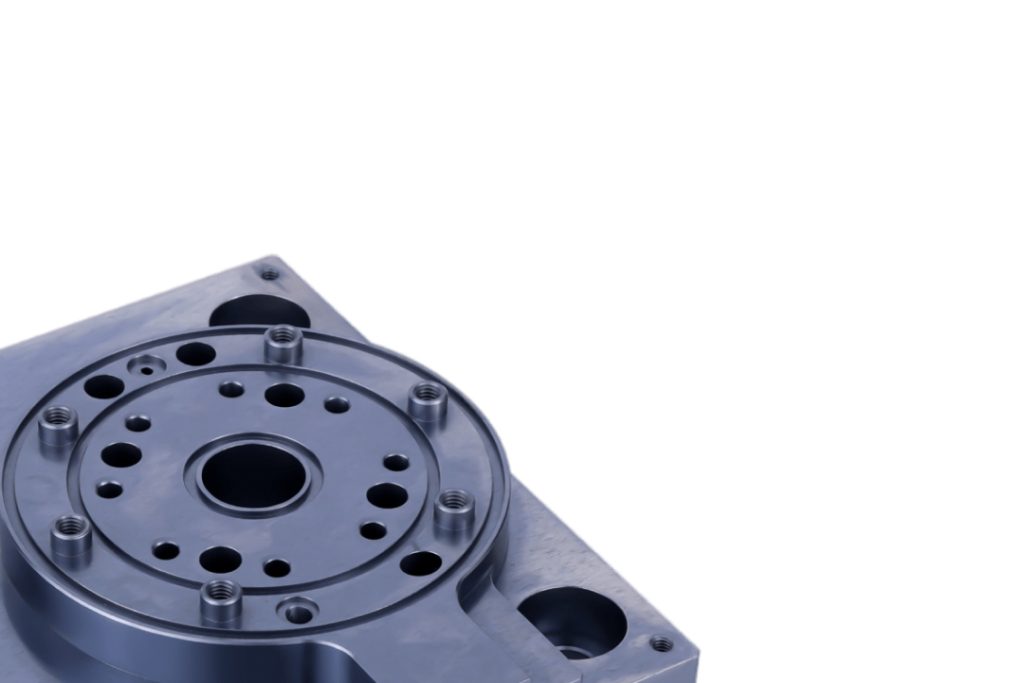

5 Axis CNC Machining Capabilities

RapidDirect’s 5-axis machining services offer unparallel speed and flexibility. With an extensive range of advanced 5-axis CNC machines and a long list of materials, RapidDirect has the capability to deliver the best 5-axis machined parts. Our experienced team and manufacturing capabilities help rapidly design and fabricate complex, time-sensitive components. With world-class equipment, expertise, and experience, RapidDirect uses two outstanding setups to provide precise, complex parts.

Simultaneous 5 Axis CNC Machining

Fast, effective, and continuous 5-axis CNC machining with improved transitioning and surface quality. Here, we use 5-axis machining center that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functionalities to ensure efficient continuous processes and transitions.

3+2 Axis CNC Machining

Take advantage of the optimal 3+2 axis machining technology for your unique applications. The process keeps the part fixed in a specific orientation to allow the usual 3-axis machining process. Our 3+2 axis machining uses shorter, more rigid cutting tools to offer your parts better dimensional stability. Get complex CNC machined parts with tight tolerances at lower costs and cycle time.

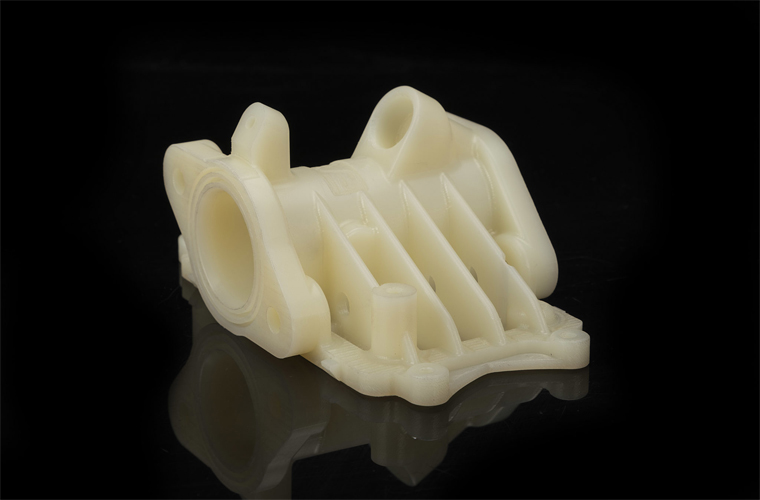

From CNC Prototyping to Production

CNC machining is a computerized and versatile manufacturing process ideal for rapid prototyping and on demand production. Here are the custom CNC services available at the RapidDirect.

Rapid Prototyping

With our instant quotation platform and strong capacity, you can get excepted prototypes in short lead times. This allows you to quickly test prototype parts and get them to market.

Bridge Production

Bridge-to-production is critical for closing the gap between the part design and the actual product rollout. No worries. Our professional engineering team is always ready to provide practical design suggestions for your low volume machined parts.

On-Demand Production

Our full service for on-demand production orders ensures that you get high precison and high standard of quality products. Enhanced production rate also allows for just-in-time delivery of production parts.

5 Axis CNC Machining Tolerances

Our ISO 9001 certification shows that we fabricate 5-axis milled parts to meet the tightest tolerance requirements. Our standard tolerance for CNC-milled plastics is ISO-2768-m and ISO-2768-f for metals. Get high-quality and precise complex parts with top-notch dimensional stability.

| Standards | Metric Units | Imperial Units |

| Maximum Part Size | 300×200×100 mm | 11.8×7.7×3.9 in. |

| Minimum Part Size | 4×4×4 mm | 0.1×0.1×0.1 in. |

| Minimum Feature Size | Φ 0.50 mm | Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-f

Plastics: ISO 2768-m | |

| Linear dimension | +/- 0.025 mm | +/- 0.001 in. |

| Hole diameters (not reamed) | +/- 0.025 mm | +/- 0.001 in. |

| Shaft diameters | +/- 0.025 mm | +/- 0.001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

| Threads and Tapped Holes | Standard size: Diameter: standard drill bit sizes; depth: 4×diameter Maximum size: Diameter: Φ 1 mm; depth: 10×diameter RapidDirect can produce threads of any specification and size required by our customers. | |

| Text |

For plastic and soft materials: minimum width of 0.457 mm, depth of 0.3 mm For hard material: minimum width of 0.838 mm, depth of 0.3 mm | For plastic and soft materials: minimum width of 0.018 in., depth of 0.011 inch For hard material: minimum width of 0.033 in., depth of 0.011 inch |

| RapidDirect can use CNC engraving or laser carving to create standard text based on customers’ requirements. | ||

| Lead Time | 10 business days for less than 50 parts | |

Materials for Custom 5 Axis CNC Machining

Our 5-axis milling services are compatible with a wide array of materials, ranging from metals to plastics. Depending on your applications, you can choose from the over 50 production-grade materials we offer at RapidDirect. See our list of 5-axis CNC machining materials. You can also contact us to discuss your unique requirements.

Aluminum

Copper

Brass

Stainless Steel

Titanium

Plastics

Aluminum

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

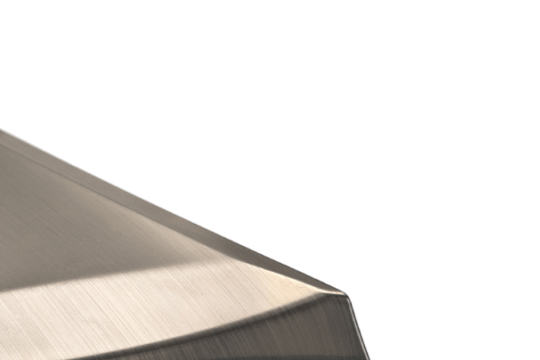

Surface Finishes for CNC Milling

Gain access to quality surface finishing for custom CNC milling parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

Name

Description

Materials

Color

Texture

Link

Anodizing

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Aluminum

Clear, black, grey, red, blue, gold.

Smooth, matte finish.

Bead Blasting

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

ABS, Aluminum, Brass, Stainless Steel, Steel

n/a

Matte

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Aluminum, Stainless Steel, Steel

Black, any RAL code or Pantone number

Gloss or semi-gloss

Electroplating

Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common.

Aluminum, steel, stainless steel

n/a

Smooth, glossy finish

Polishing

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection.

Aluminum, Brass, Stainless Steel, Steel

n/a

Glossy

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

ABS, Aluminum, Brass, Stainless Steel, Steel

n/a

satin

Ultimate Guide to CNC Machining

5 Axis CNC Machining Facilities

RapidDirect implements strict quality control protocols to ensure that every client receives superior-quality products. We have dedicated workshops with state-of-the-art equipment for a wide range of operations. This way, we incorporate meticulous inspection in our 5-axis CNC machining processes.

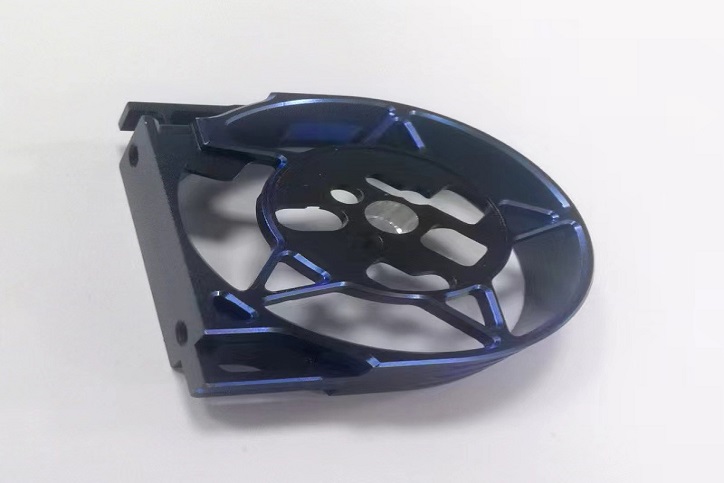

Applications of 5 Axis Milling

Our 5-axis milling services is your best bet when it comes to manufacturing complex, highly precise components for a wide range of industries. Our manufacturing capabilities allow us to accelerate the production of several components, including:

- Automotive components: Engine housing, light guides, valves, engine covers, inspection jigs

- Aerospace parts: Fuselage sections, bulkheads, landing gear components

- Medical and Surgical tools: Forceps, scalpels, spacers, clamps, cutters, surgical scissors

- Military components: Submarine parts, turbine blades, engine parts, weapons, sensors

Gallery of CNC Milling Parts

Tour Our 5 Axis Machine Shop

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

Why Choose Us for CNC Milling Service

At RapidDirect, we are committed to helping you reach your manufacturing goals. We constantly strive for effective solutions through our progressive technological approaches and machining techniques. Our CNC milling services ensure you get highly precise prototypes and production parts with superior quality.

High Precison

We manufacture prototypes and low-volume production parts at high precision. Our CNC 5-axis milling services can achieve standard tolerances of +/- 0.05mm. However, we can also reach tighter tolerances of up to +/- 0.01mm.

Handle Complex Design

Our machining centers can machine intricate parts with complex geometric features. With comprehensive material knowledge and 5-axis machining capabilities, we can manufacture components to meet your unique demands.

Instant, Free Quotations

Our online quotation platform allows you to easily upload your design files to get instant, free quotations. This prevents the strenuous back-and-forth that comes with the traditional ordering process. Furthermore, we will provide a free DFM analysis report to show you possible design errors that may make machining difficult. This will help you save costs and time.

Smooth Finishes

The 5-axis machining process gives quality as-machined surface finishes. Asides from this, the process is compatible with various surface finishing. We can apply surface finishes like plating, polishing, bead blasting, etc., on your 5-axis machined parts. These finishes offer better surface qualities and mechanical properties to the machined components.

High Produdction Speed

We boast a machine shop with 5-axis machining centers in-house. This capacity helps us create prototypes and low-volume production parts in days. Our simultaneous 5-axis machining allows continuous machining without stoppage, thereby ensuring faster production.

24/7 Engineering Support

RapidDirect provides experienced service engineers to answer all your 5-axis CNC service inquiries. Our experts are always on ground to deliver top-notch engineering support to help you get the best result from your project.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Piscary Herskovic

Product Designer

Mark Alford

Chief Engineer

Luc Szorc

Mechanical Engineer

Kayne Espinosa

Project Manager

Hari Mackenzie

Engineer

Our 5 Axis CNC Machining for Various Industrial Applications

RapidDirect works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Semiconductor

Speed up time-to-market in the semiconductor industry through on-demand CNC production, responding quickly to market demands and advancements.

Robotics

Enhance efficiency and accuracy in robotics with CNC-produced components, contributing to optimal system performance.

Aerospace

Our CNC technology optimizes aerospace production for efficiency and faster delivery, ensuring precision in complex components that enhance aircraft performance and safety.

Automotive

Achieve precision beyond industry standards with our CNC capabilities, producing components that elevate vehicle efficiency, safety, and performance.

Automation

Speed up product development and testing for rapid market entry in the automation sector, using our CNC technology to bring innovative solutions to life.

Consumer Products

Respond swiftly to market trends by swiftly creating cost-effective new products with our CNC solutions, transitioning seamlessly from concept to production.

Communication

Our CNC technology accelerates design and manufacturing, helping you create high-performance communication products that stay ahead of the curve.

Electronics

Achieve precision enclosures for electronics, even in low-volume production, using our CNC technology to ensure design and functionality excellence.

Industrial Equipment

Manufacture components that outperform competitors and enhance overall performance in the industrial equipment sector with our CNC capabilities.

New Energy

Innovate and develop new energy solutions faster with our CNC solutions, iterating and refining prototypes efficiently.

Medical Devices

Our CNC technology supports the creation of precise, safe, and compliant medical device prototypes and products.

Our CNC Milling for Various Industrial Applications

1. When should I choose 5-axis CNC machining?

The flexibility of 5-axis CNC machining allows the creation of complex components with complex shapes and geometrical details. The stability of the machining tool also gives more consistent and smoother surface finishes. Therefore, you should choose 5-axis machining whenever you need to produce complex parts with tight tolerances.

2. What’s the maximum part size for 5-axis CNC machining?

Our 5-axis milling machines can accommodate a length of 42 inches bar stock. This allows us to work on a wide range of projects for various applications.

3. How much does your CNC machining service cost?

The cost of your CNC machining projects is not fixed as it depends on the characteristics of your project such as the design, and tolerances. Machining times of the material to be used in the project also contribute to this pricing. For example, if you’re making a part that has a combined machining and material cost of $2 and a setup cost of $200, one part will cost $202. However, if you make 200 parts, each would cost $3!

Explore Related Resources

Multi-Axis Machining: 3-Axis vs 4-Axis vs 5-Axis CNC Machining

Selection of the right type of machine in multi-axis CNC machining is among the most crucial decisions. It determines the overall capabilities of the process, the designs that are possible, and the overall costs. 3-axis vs 4-axis vs 5-axis CNC machining is a popular debate and the right answer depends on the requirements of the project. This guide will…

CNC Machining Materials: Choosing the Right Materials for CNC Machining Project

CNC machining is inarguably the lifeblood of the manufacturing industry with applications such as aerospace, medical devices, and electronics. In recent years, there have been incredible advancements in the field of CNC machining materials. Their wide portfolio now offers great combinations of material properties, cost, and aesthetics. In this article, we will delve into the diverse world…

Plastic CNC Machining: Create Custom CNC Machined Parts with Accuracy

A common depiction of CNC machining, most times, involves working with a metallic workpiece. However, not only is CNC machining widely applicable to plastics, but plastic CNC machining is also one of the common machining processes in several industries. The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC…